song_spectrograph_assembly

This is an old revision of the document!

Table of Contents

Room requirements/setup

Optical bench mounted on active support system: PFA51507 - 700 mm (27.5“) Active Isolation Frame 900 x 1200mm (36” x 48“). Requires compressed air regulated to 50-100 psi.

External table/shelf for camera pump, computer relay/thermister/watchdog (on DIN rail?)

Power needed for:

- computer (and monitor for testing)

- power supply for QHY camera (power to camera is routed through watchdog with relay reset)

- power for cooling pump

- power for alignment laser

- power for LED source

- power for FPU iodine stage (FPU testing only)

- power for FPU calibration stage (FPU testing only)

- power for calibration box (FPU testing only)

- power for high voltage source (FPU testing only)

- power for iodine cell temperature controller (FPU testing only)

Ethernet connection needed for spectrograph computer.

USB:

- USB3 to hub : alignment camera, autocollimator camera, Esatto focuser, Zaber stage (FPU testing only), Atik camera (FPU testing only)

- USB2 to hub: QHY power relay, QHY thermister, keyboard, mouse

- USB3 : QHY camera

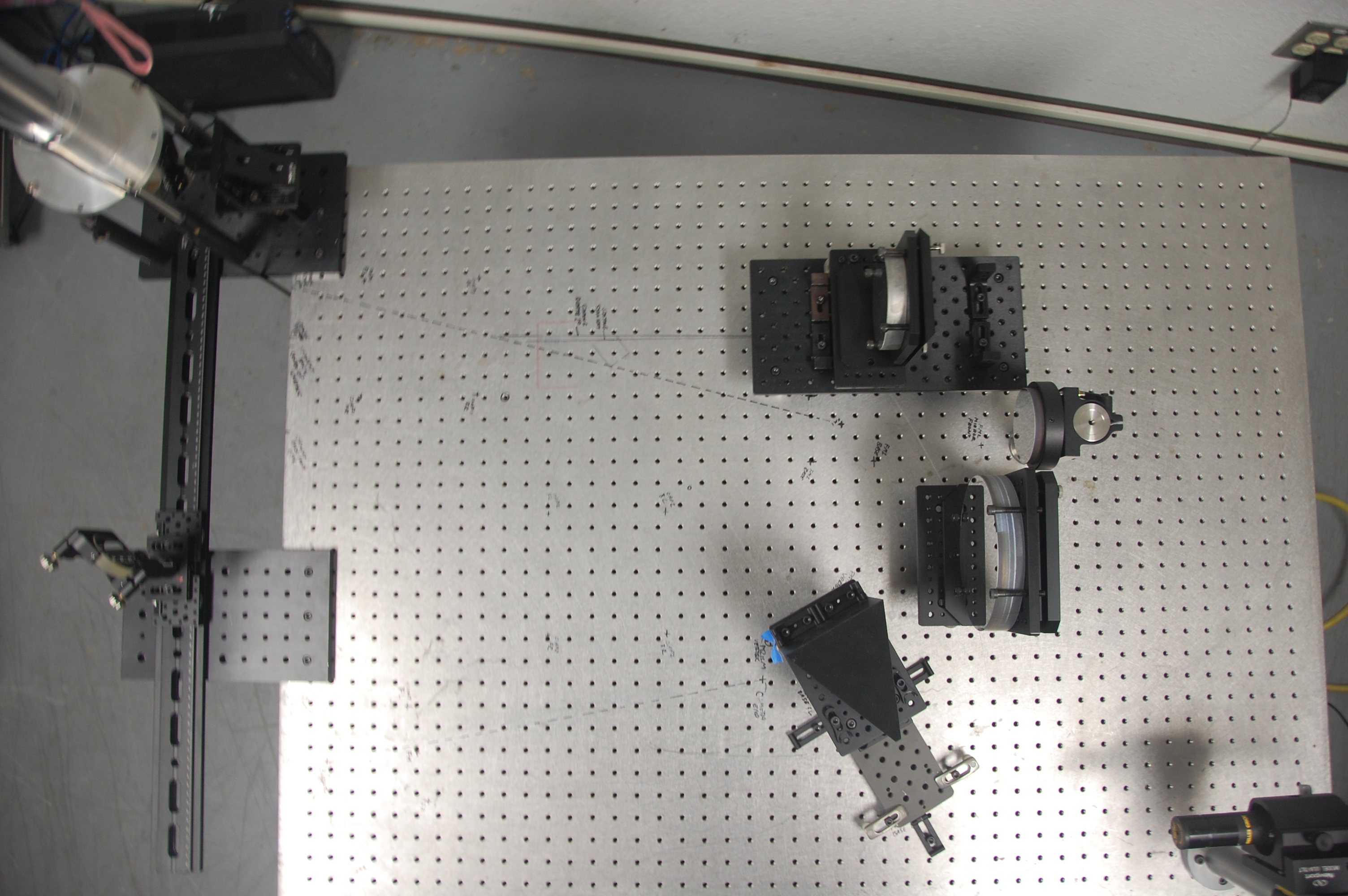

Spectrograph components

- 4×3 foot optical table on vibration isolation legs

- upper table and legs

- input fiber unit

- input LED source

- 100mm lens assembly

- (removable) beam splitter

- laser input

- (removable) beam splitter

- slit viewing camera

- right angle unit and 100mm (?) reimaging optics

- slit

- collimating telescope mount, rail with two diagonal mirrors

- FM1 and mount

- OAP1 and mount

- grating and mount and grating mirror and mount

- FM2 and mount

- OAP2 and mount

- FM3 and mount

- prism and mount

- camera and mount

- ESATTO focusser

- QHY camera

- liquid cooling system

- computer and monitor

SONG spectrograph assembly

- Prepare optical table with acceptable support and sufficient access on all sides (while attempting to minimize total footprint

- position legs

- put table on legs

- connect compressed air (50-100 psi)

- adjust valve on leg D to get ~9mm clearance from bottom of table to leg structure (takes a few minutes for air to raise table)

- ajust valves on legs C and B to get level table

- Mark optical table with locations of mounts based on lab measurements

- Install collimating telescope behind table.

- install laser for collimator mirror alignment at far corner of table

- adjust laser to ensure correct height and (175mm?) light parallel to table. Use pentaprism to get long baseline measurement of beam height at ~2 table lengths with reflection, Laser to pentaprism on top of tube with 1-inch circular mirror at bottom, then light comes back up and back towards laser: rotate pentaprism slightly to measure height with measuring stick.

- Adjust diagonal mirrors to ensure proper alignment

- far diagonal tip-tilt to retun laser back to source

- rotate far diagonal to direct towards diagonal under collimator

- adjust diagonal under collimator to get beam in collimator.

- set up upper table on main optical bench in correct location. Install:

- fiber input,

- collimating assembly. Check with auto-collimator.

- laser input via removable beam splitter,

- camera output via removable beam splitter, Check with auto-collimator?

- output focusing lens.

- Check alignment with laser, ensure camera functionality. Install slit to ensure focal plane is at desired height above optical table

- Install FM1 at desired height. Position to get desired deflection angle

- Install grating mirror and align with collimating telescope

- Install FM2 and align with collimating telescope (do now to ensure consistency with grating mirror)

- Install FM3 and align with collimating telescope (do now to ensure consistency with grating mirror)

- Install OAP1. Adjust initial height and tilt using autocollimator off mirror on back of mount. Adjust lateral so laser falls at appropriate location on the OAP (52mm from edge?).

- Align OAP1 using 10micron fiber input to minimize aberration

- Rotate spectrograph mirror to get 15mm separation between input and output laser. Adjust further to ensure that reflected beam misses FM1.

- Install OAP2. Adjust initial height and tilt using autocollimator off mirror on back of mount. Adjust lateral so laser falls at appropriate location on the OAP.

- Rotate FM3 so that return beam goes back into camera.

- Align OAP2 using 10 micron fiber input to minimize aberration

- Install prism. Rotate FM3 to ensure correct beam location

- Install camera. Adjust to ensure correct beam location: no light falling outside any optic

- Image cross-disperser fiber. Ensure expected width. Adjust detector to make vertical spectrum. Rough prism adjustment to get laser at correct location on detector.

- Install grating.

- Adjust grating tilt and prism to ensure good spectral coverage: grating so that peak of blaze function near center of detector, and prism to ensure good wavelength coverage.

song_spectrograph_assembly.1746122612.txt.gz · Last modified: by holtz